On Thursday 12th March I flew down to Newquay to visit CCP Ltd – Cornish Concrete Products – to review production on the first set of bespoke benches for Southampton Station Quarter. I was meeting up with Simon Taylor, Urban Design Manager – Southampton Highways Partnership, Balfour Beatty Living Places, who is the Design Manager for the Station Quarter project. Simon met me at Newquay Airport & we drove down to Bissoe to CCP’s manufacturing plant.

I left Ramsgate on High Speed 1 for London, St Pancras, then by Tube to Victoria to pick up the Gatwick Express & Gatwick to Newquay by Twin Prop and from there by car to Bissoe – easy ! A great day – but one delay along the way could have been a disaster – fortunately it was brilliant.

Image: Christopher Tipping

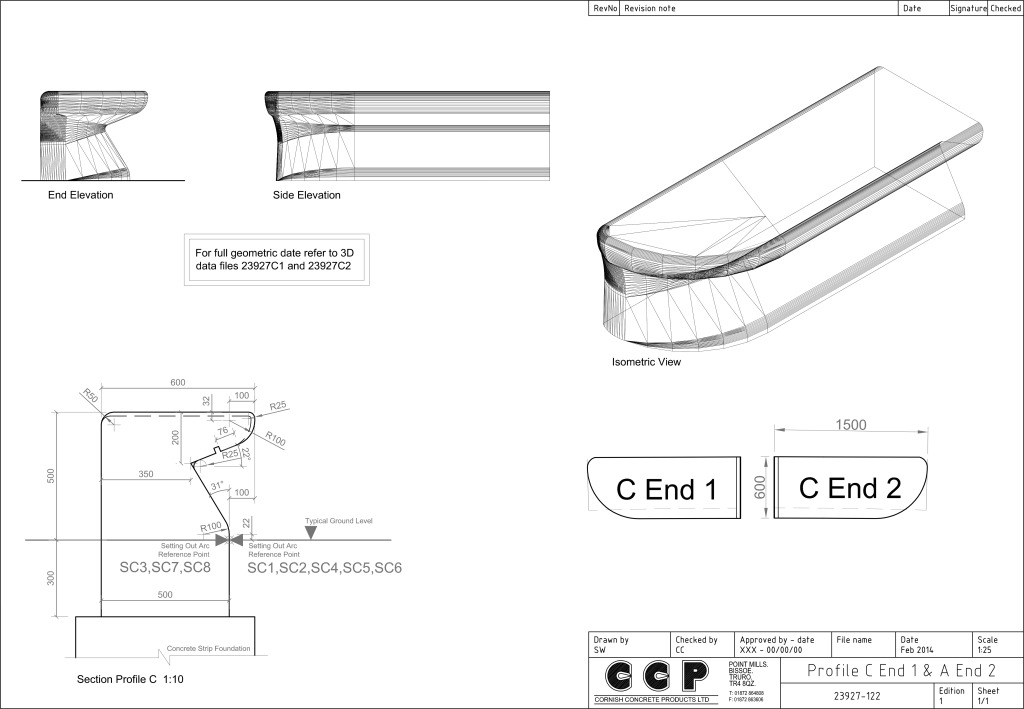

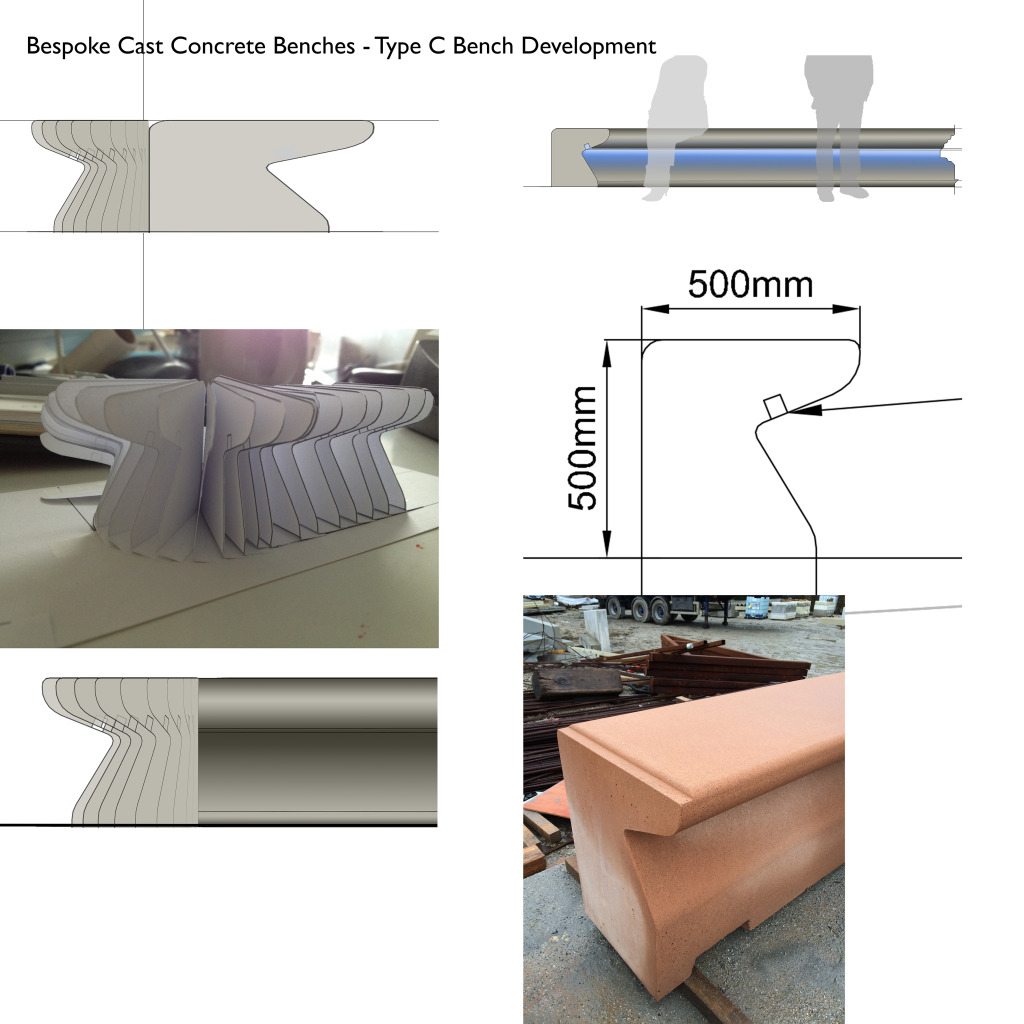

The units below are the first to be manufactured and are, as such the sample test for the project. We will be looking to iron out any issues presenting at this stage and develop a methodology for ensuring quality control through the production period. The Type C unit – is only one of several bespoke profiles being developed – with each profile there are accompanying bespoke ends and specials to be made.

This is a single unit, part of a six unit seating set for the landscape works. The seating forms part of the interpretation and public art created for the project. The units as seen here have yet to have the etching treatment to expose the surface aggregates, so appear quite light in colour. The finished colour and aggregate mix reflect the multi blend granite paving used throughout the site and is informed by the geology of the site – alluvial gravels – which were at one time quarried nearby in the area now occupied by the Civic Centre. These gravels would have formed the beach of the River Test Estuary, which was – until 175 years ago – to be found where Blechynden Terrace now stands.

We have selected the Blackhill Aggregate – White Cement – Heavy Etch sample to work with –

The composite image below, illustrate the evolution of the Type C Bench. The basic section is added to with bespoke and varying ‘ends’, with some units being further cast with lighting recesses.

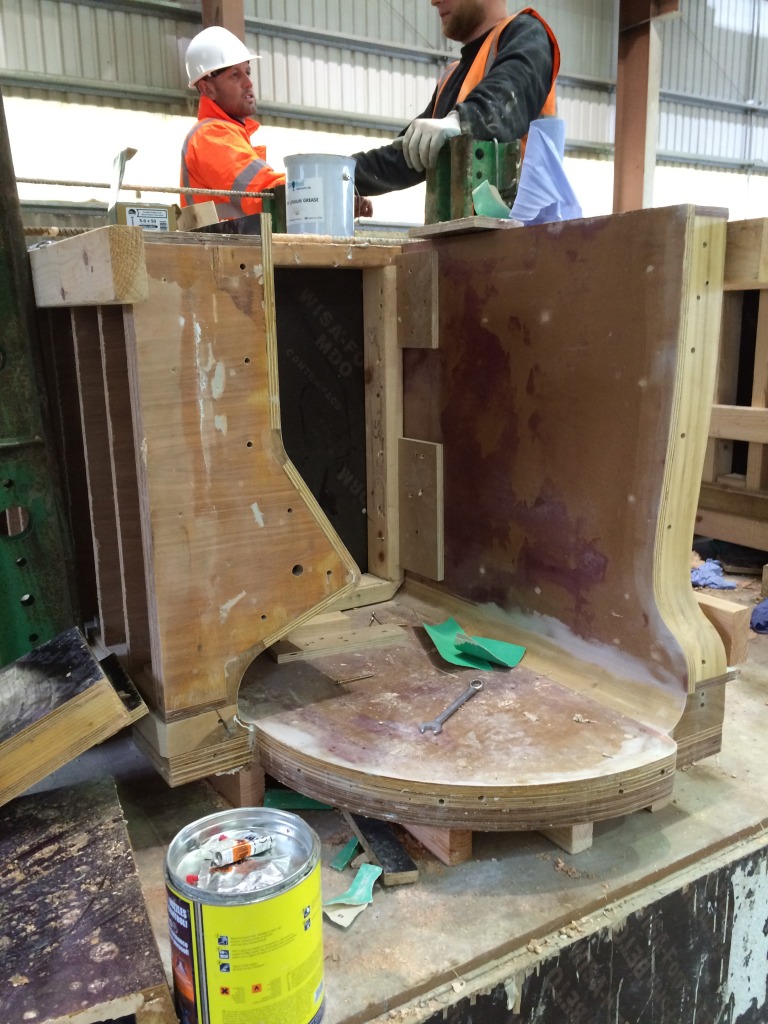

I particularly like to see the timber joinery and craftsmanship which goes into the moulds. No-one else really sees this – and the general public generally have no idea of the work that goes on behind the scenes to achieve the objects they see in the public realm.