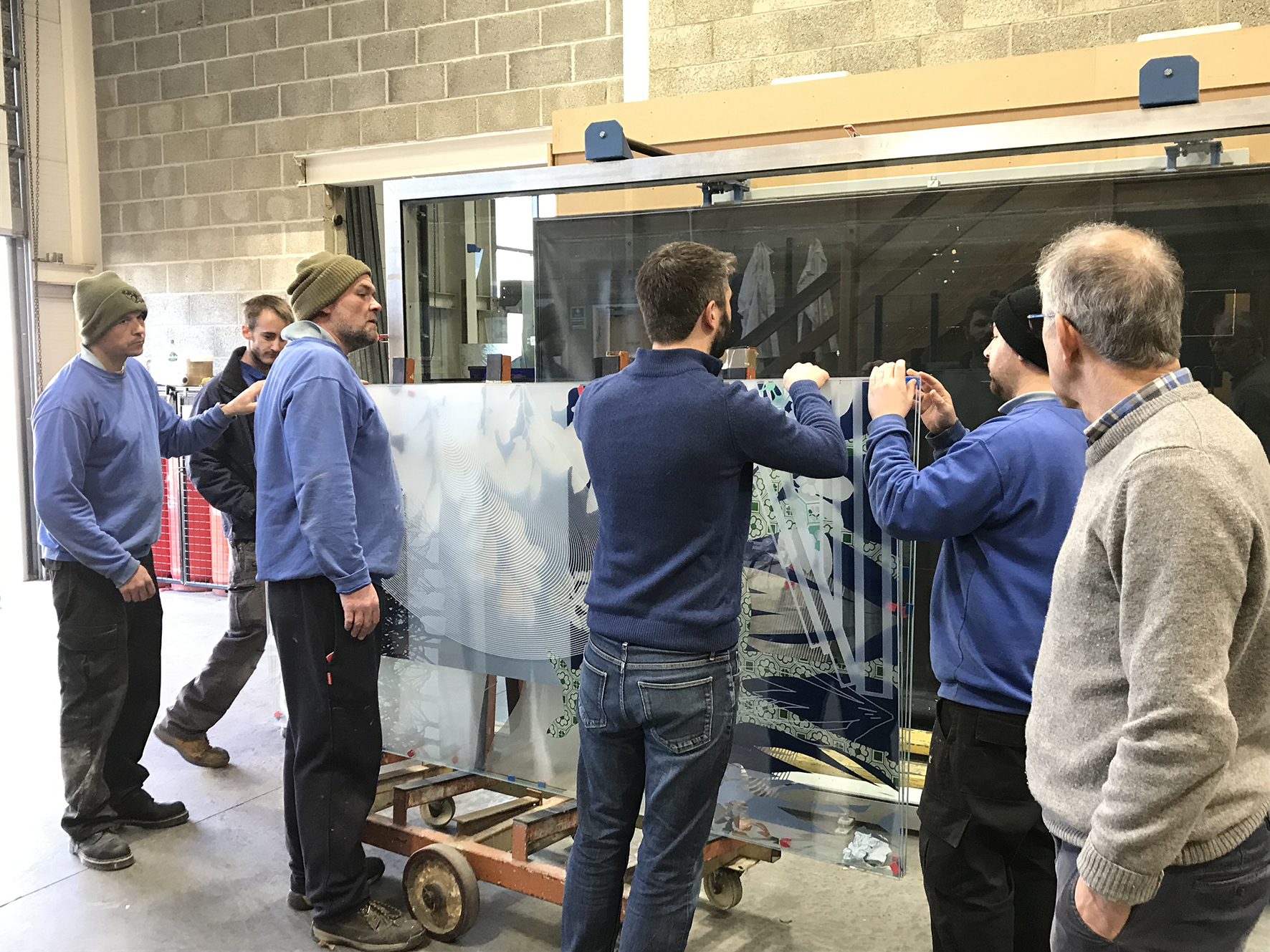

Working with David and Richard at Proto Glass Studios is always a delight. What they do is exemplary and they work hard to collaborate in achieving the very best outcome for the artwork and the artist.

My visit to their workshops near Pewsey in Wiltshire on Thursday last week was a catch up on progress after Christmas. I had made a visit previously to this before Christmas along with clients from ‘Art at the Heart’ at the RUH, which has still not been posted.

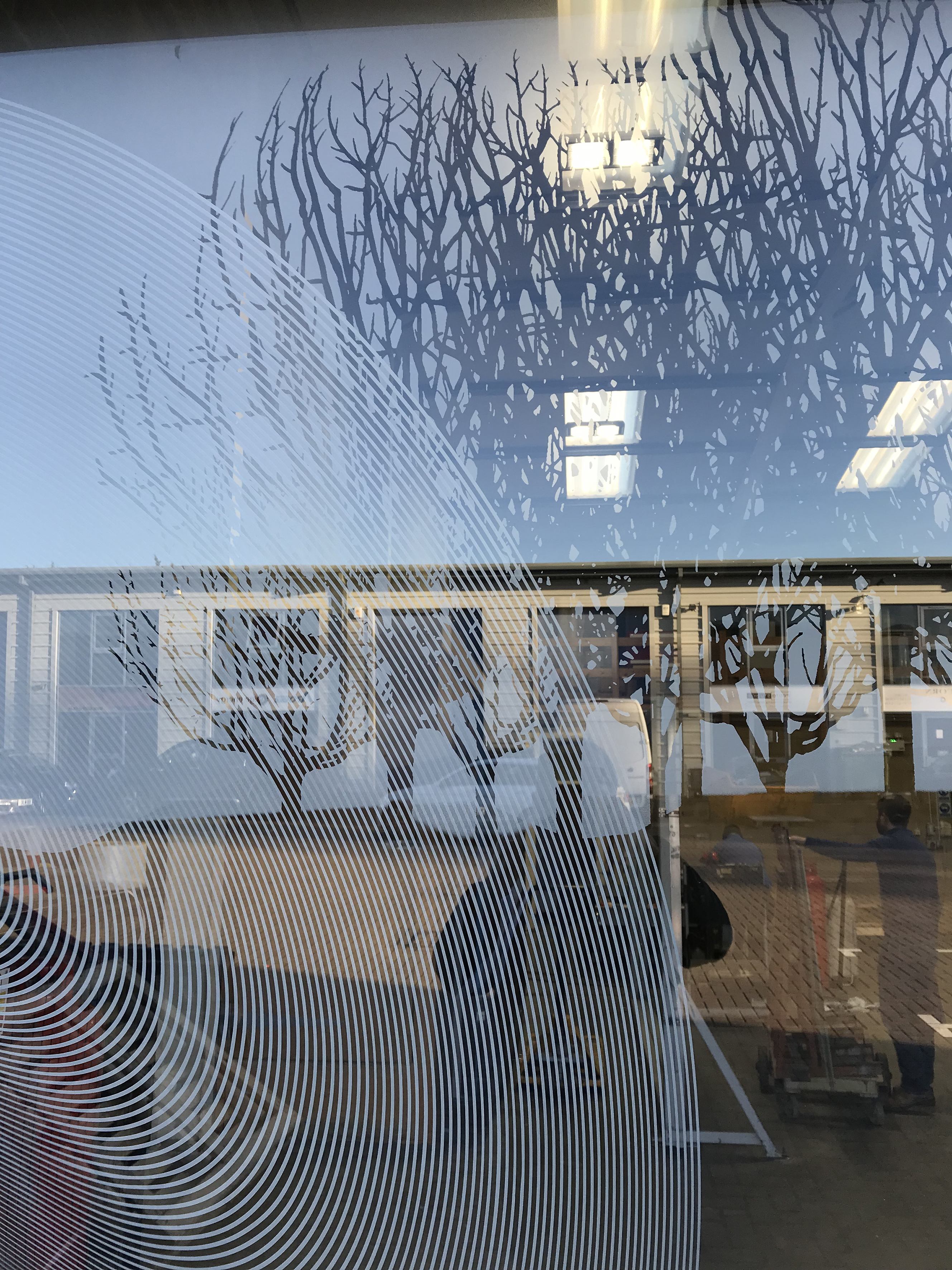

All the glass panels have now been printed & etched. They were then sent away for toughening – a heat process, where the glass is tempered in a furnace to temperatures close to 600 degrees C and then cooled rapidly. Following this process, the glass can be sandblasted with additional layers of detail. Once completed, the panels will finally be made into sealed units for delivery to site and installation.

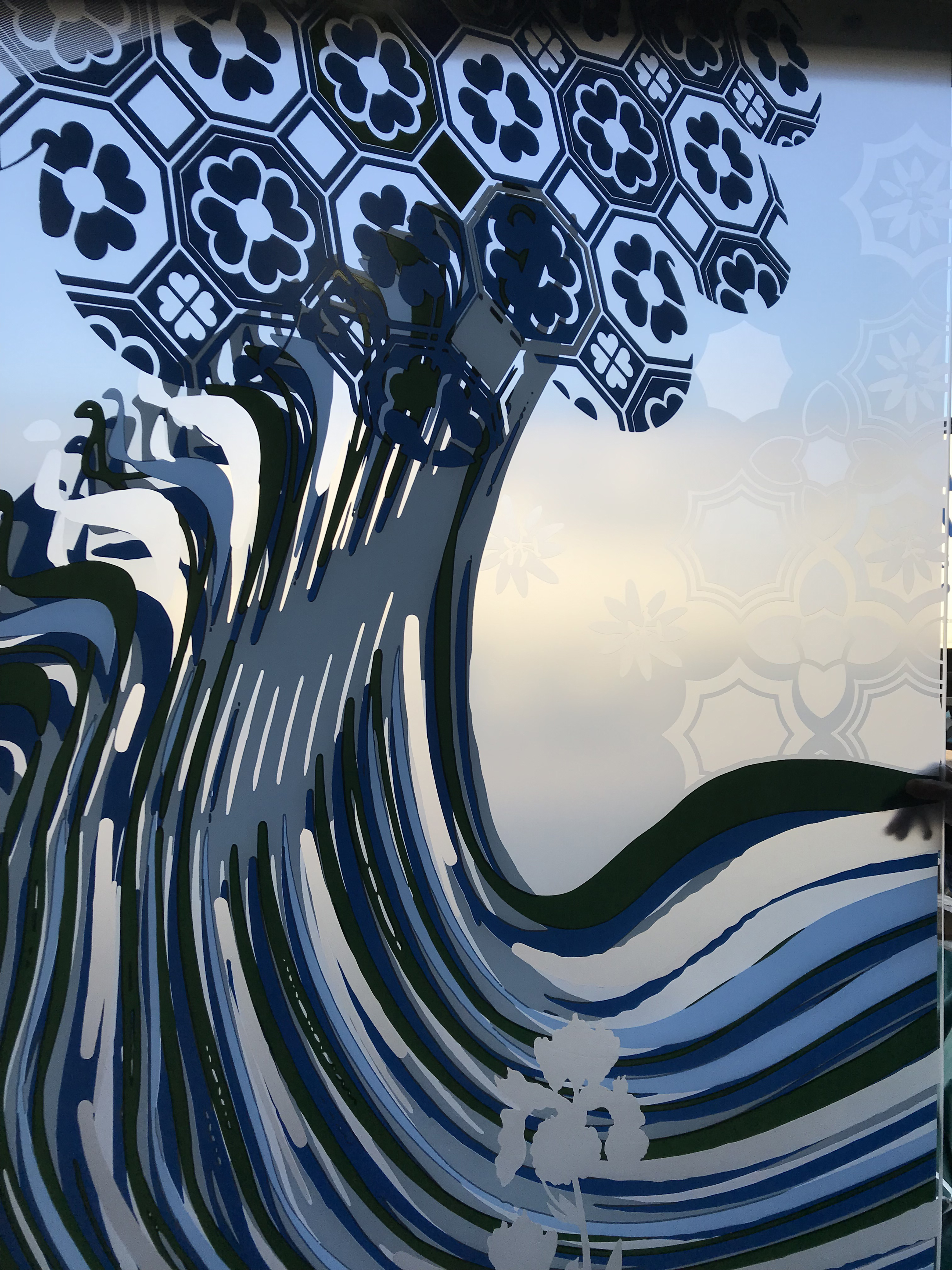

The architectural glass screens total some 46sqm of glazing. However, the screens are made up of double sealed units – two panels of glass with a gap in-between. This has allowed us to apply decoration to both panes of glass within the same sealed unit. The panel above, for example is 2500mm x 1217mm x 10.8mm. This is the largest size. There are 18 apertures in the North and East screens combined – larger spaces below and smaller spaces above with a double sealed unit in each – so a total of 36 individual panels of glass have been decorated. 18 of this total have also been laminated to another clear pane of glass. Proto have prepared and decorated all of this glass. They have handled of these elements with great skill and care.

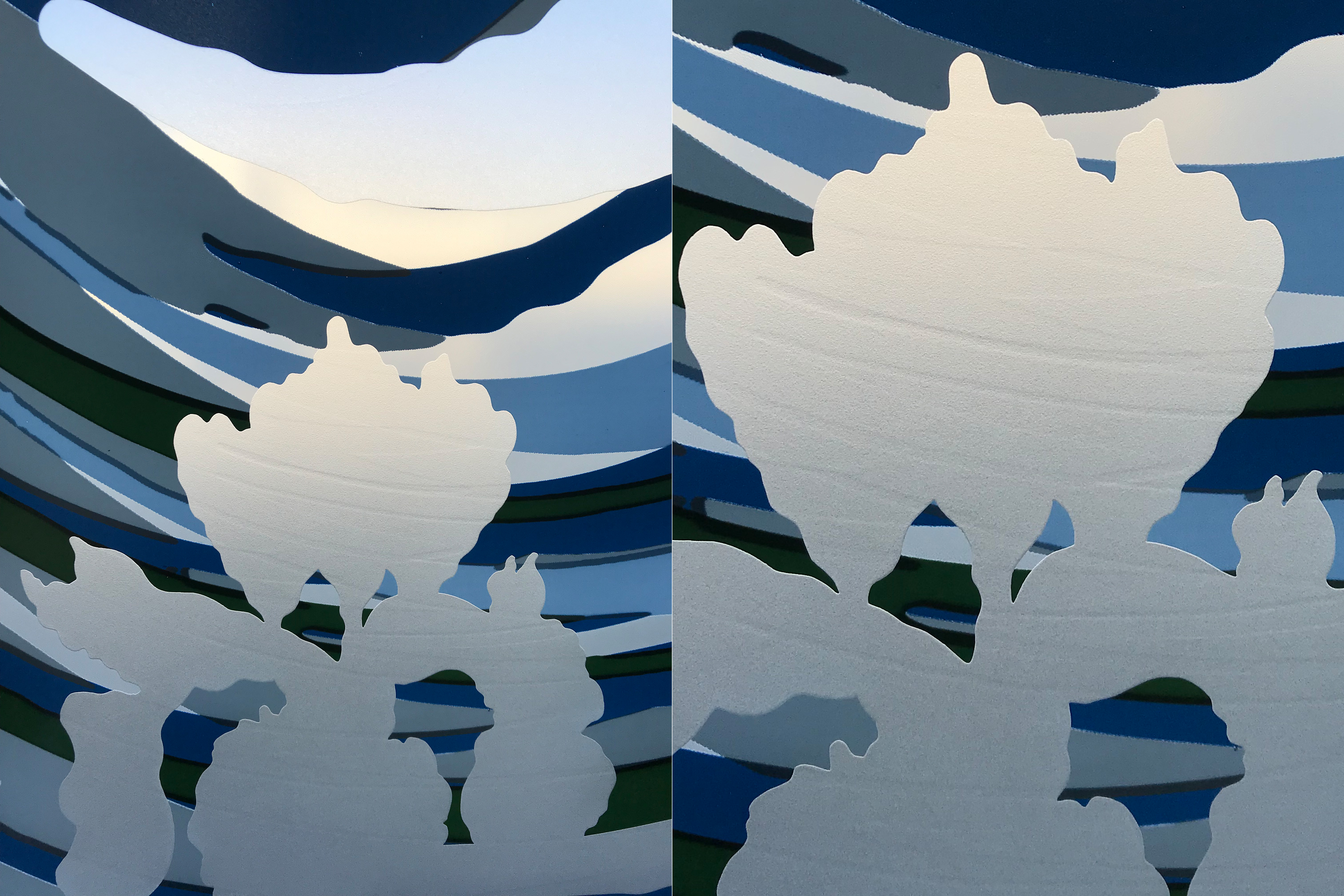

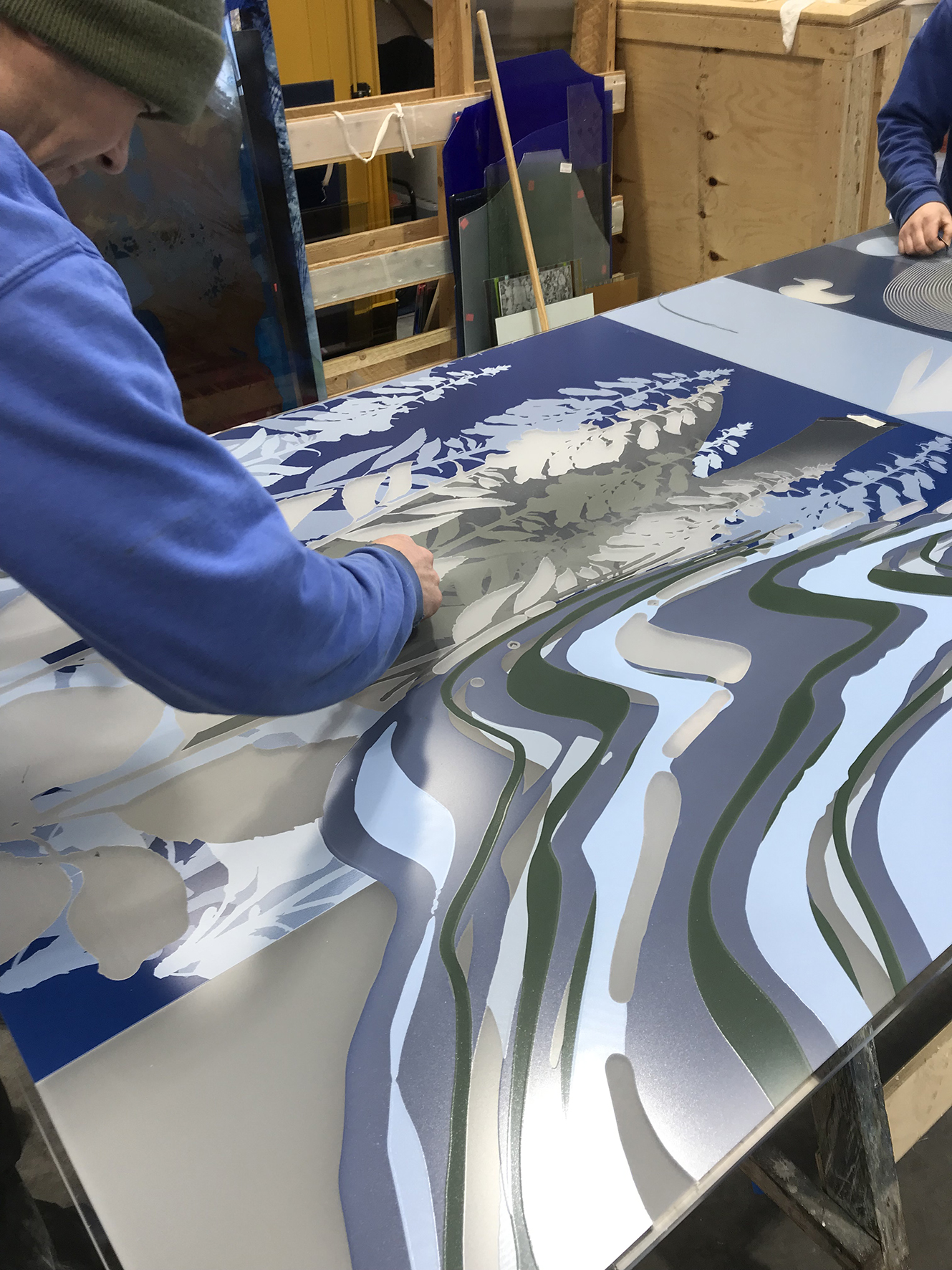

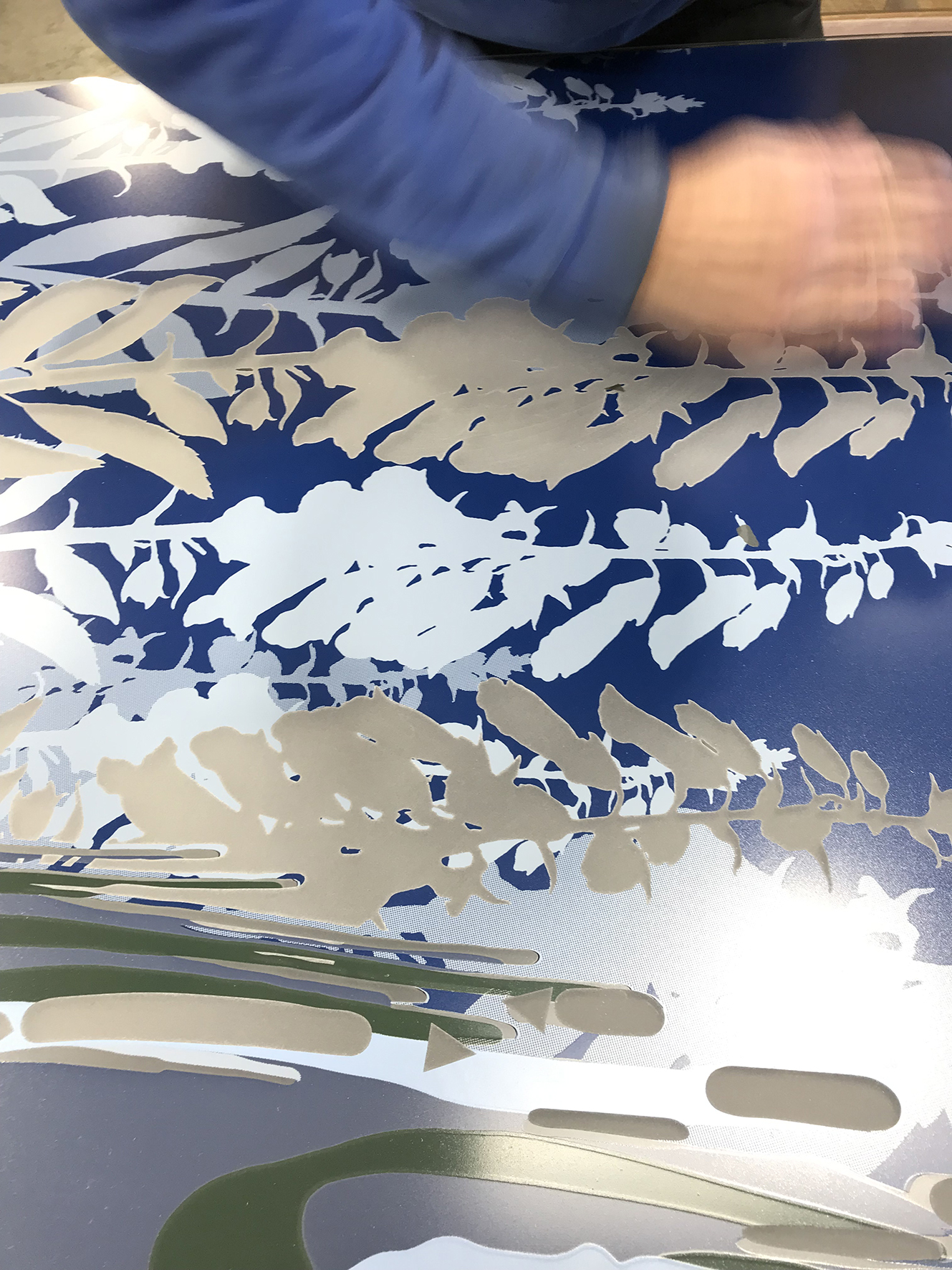

Weeding out the stencils following sandblasting.

Weeding-out stencils, cleaning and brushing away, following sandblasting of the ceramic colour screenprint.