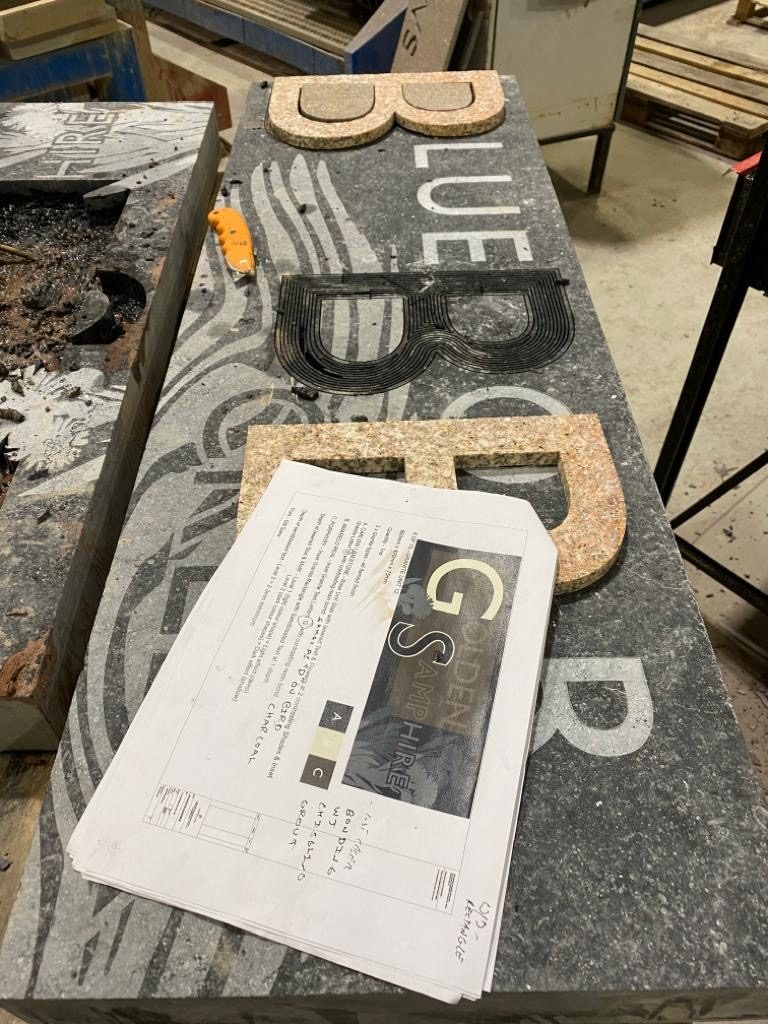

I’m travelling up north to Bolton this week to see the final units completed and hopefully sign off the work so it can be delivered to Rochester Riverside for installation. Can’t wait to see them all.

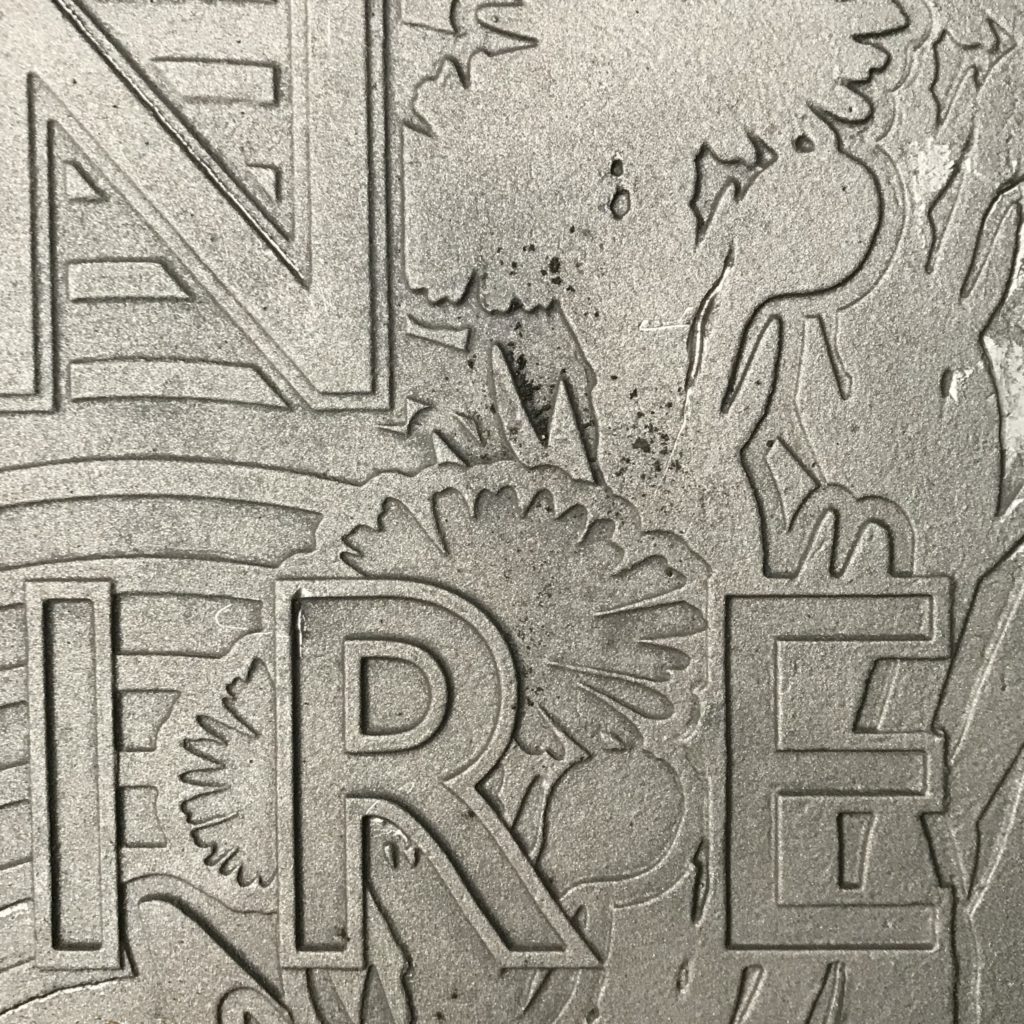

Above: “BLUE BOAR CREEK”…& other tales from Rochester Riverside. Detail of a water-jet cut & laser-etched paving panel in black Carlow Limestone with inset text of Amarelo Real (yellow granite) & Porphyry.

These new images are just in this afternoon thanks to Mathew Haslam of Hardscape – as their skilled stone specialists focus on the applied detail. Water jet cutting, inlaying, sandblasting and laser etching their way through 15 bespoke units destined to be embedded into the landscape of the new housing development at Rochester Riverside for client Countryside. This highly bespoke work needs to be handled with care and demands high levels of craft skills.

Hardscape have been excellent at providing this form creative collaboration. Public Art Strategy & Artists Commissions by FrancisKnight .

Below: This unit is 9 of 15 – ‘SHELDUCK’, a Kobra Green Granite base slab with water jet cut inset motif & text in black Carlow Limestone, which has been laser etched with surface detail. Further sandblasting of text into the green granite, will complete the work.

Above: The almost completed ‘WILLIAM CORY & SON LTD’.

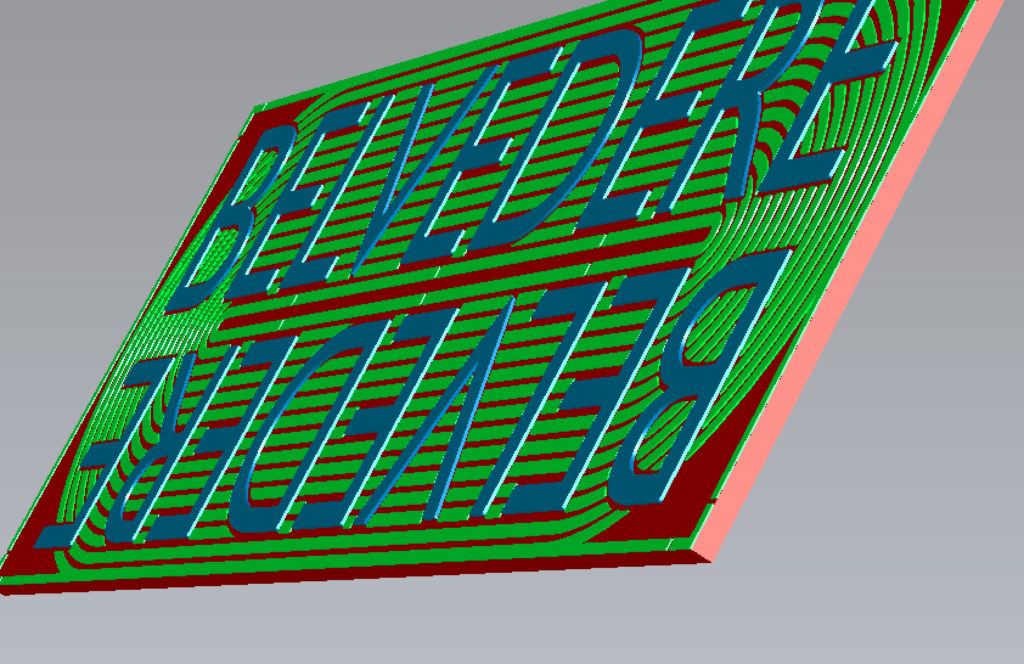

Above: This is the base slab of black Carlow Limestone, which has been laser etched first & then water jet cut – but the large letter ‘W’, the ‘&’ and the diamond motif have yet to be chiselled out. See Below –

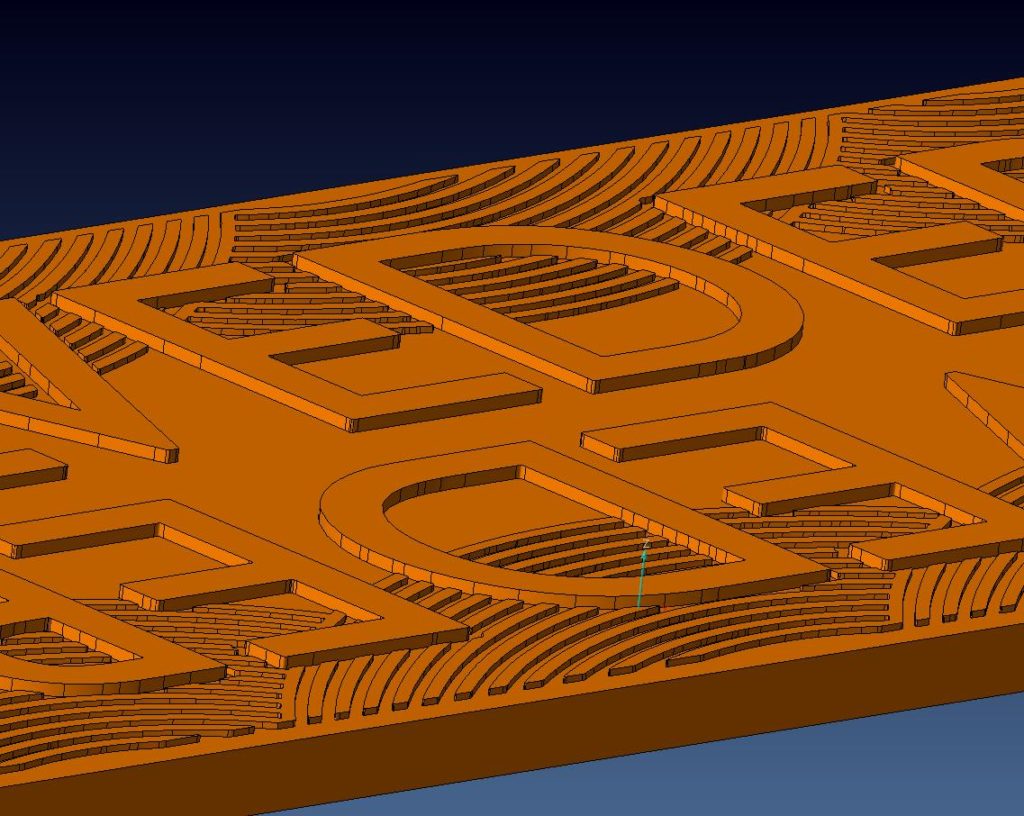

Above: The water jet cutting removes a series of lines from the granite, which are determined by the CAD programme, which creates the cutting paths. These pathways are interesting in themselves as patterns, but in this instance they have to be chiselled out carefully by hand, to create the void space for the granite inlay to be fixed.

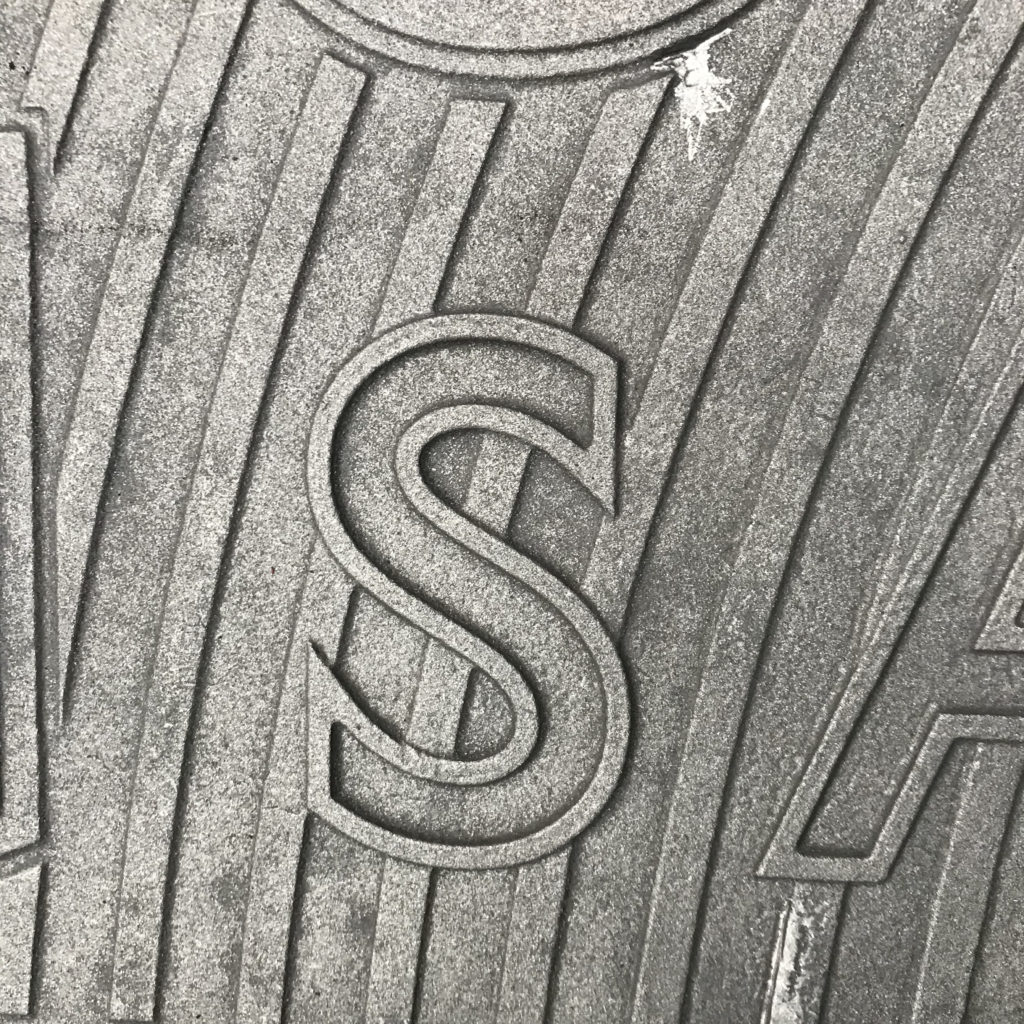

Above: This images shows the void spaces chiselled out from the Carlow Limestone. The letter ‘W’ in Maple Red granite has already been inset and is awaiting bonding in place – the diamond motif is just about to be inset. These images are wonderful for showing process, craft and the mix of skills from CAD technology to work by hand & eye.